I build a small device to test the orthotropy of Manner Schnitten (a famous Austrian biscuit, consisting of layered waffles with hazlenut creme in between).

The idea was to test, if and how the biscuit would break when the waffles are parallel or perpendicular. In theory, the force required should be larger for the perpendicular case.

I thought about a simple hydraulic mechanism to test it. Syringes would be ideal, I thought, as they are quite cheap and easily available. I would just need to measure the pressure. Good I had a pressure transducer from my Gaggia Pressure Project (no, not the analog one. I bought a digital transducer a while ago but had problems to fixate it in the machine...).

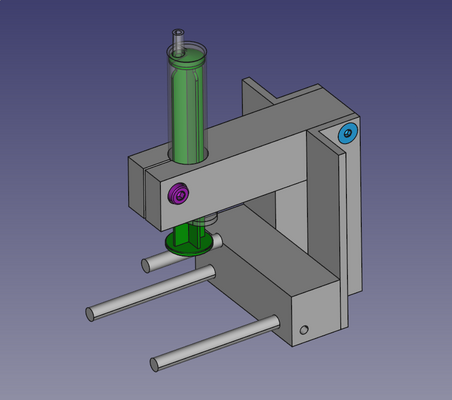

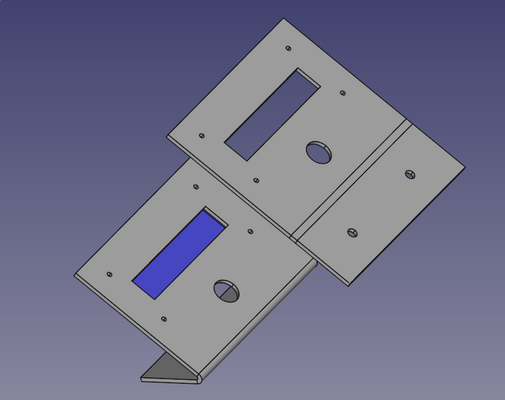

Everthing started with a sketch in FreeCAD:

Using the Sheet Metal workbench, I was able to easily create a drawing for the bended Aluminium frame.

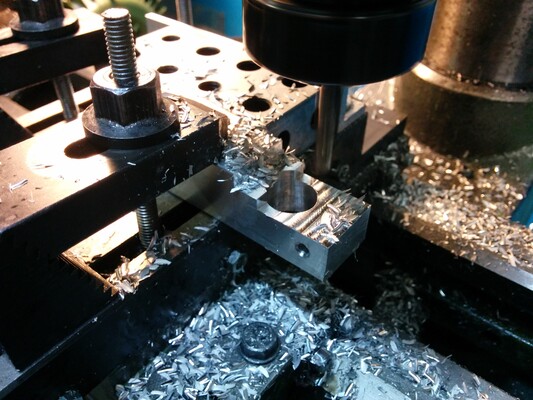

Next, I used the mill in Metalab to create the aluminium frame for the syringes. Here are at least two fotos from the creation process:

Using an old Arduino Uno and a even older Protoshield (which had some other components on it already), I hacked together the software. It reads the sensor value and converts it to mbar. Knowing the area of the syringe, I can convert to the force which acts on the piston.

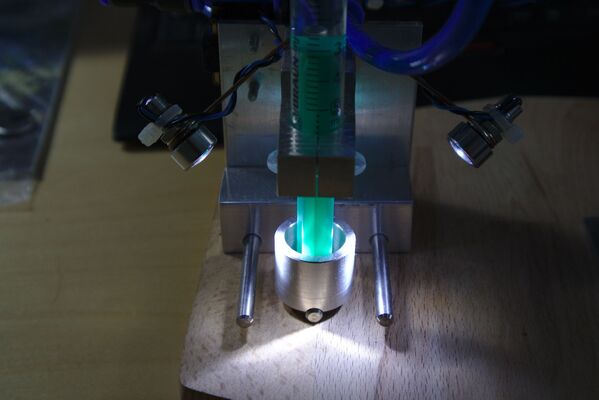

But now for some images!

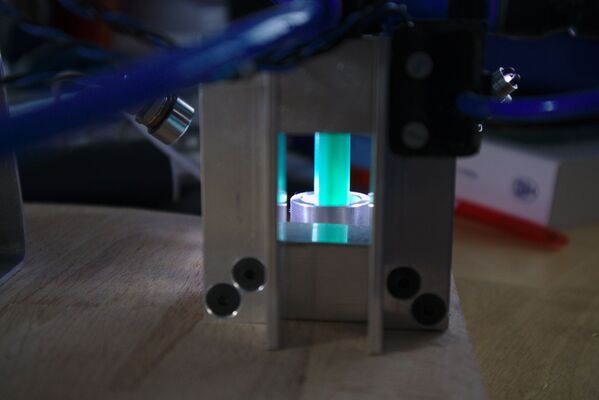

The piston

The display unit

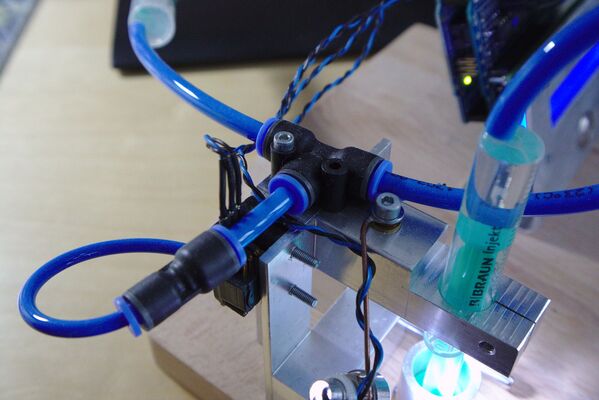

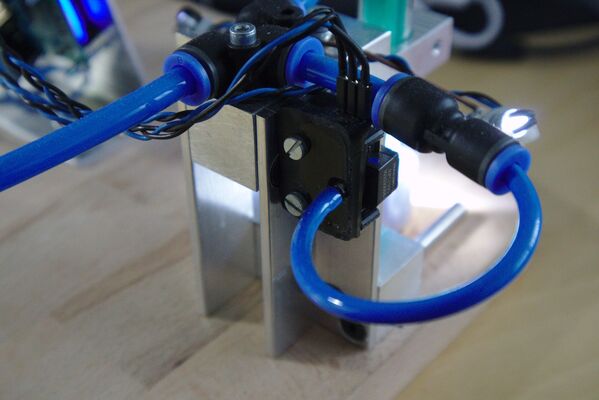

Hydraulic mechansim. I used distilled water as medium.

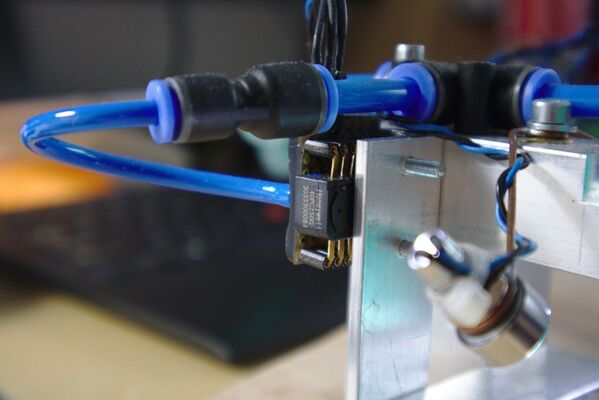

Pressure transducer unit

The piston seen from the back

Arduino unit (the IC's on the protoshield are not used)

Pressure transducer

Starting up!

Parallel configuration

During the measurement

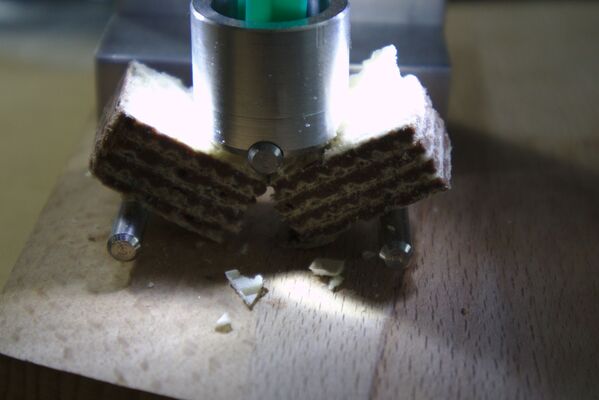

Maximum force is when it breaks (if you are careful...). Reading 24.74N in parallel configuration

Broke to pieces...

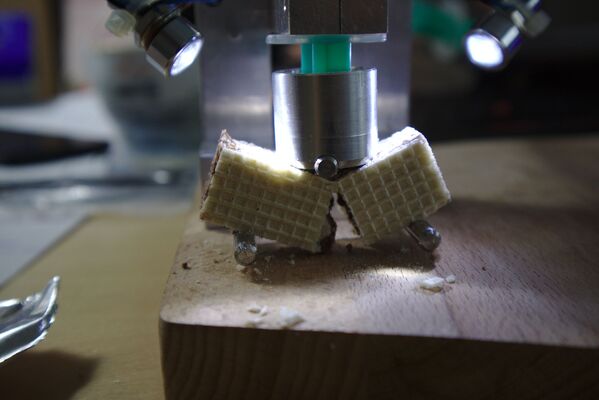

Now the same for the perpendicular configuration: 32.69N! Theory confirmed ;)

The break is much cleaner too

The Piston top